Industrial IoT - Smart inventory management

Eliminate manual and paper-based processes

The Industrial IoT difference

-

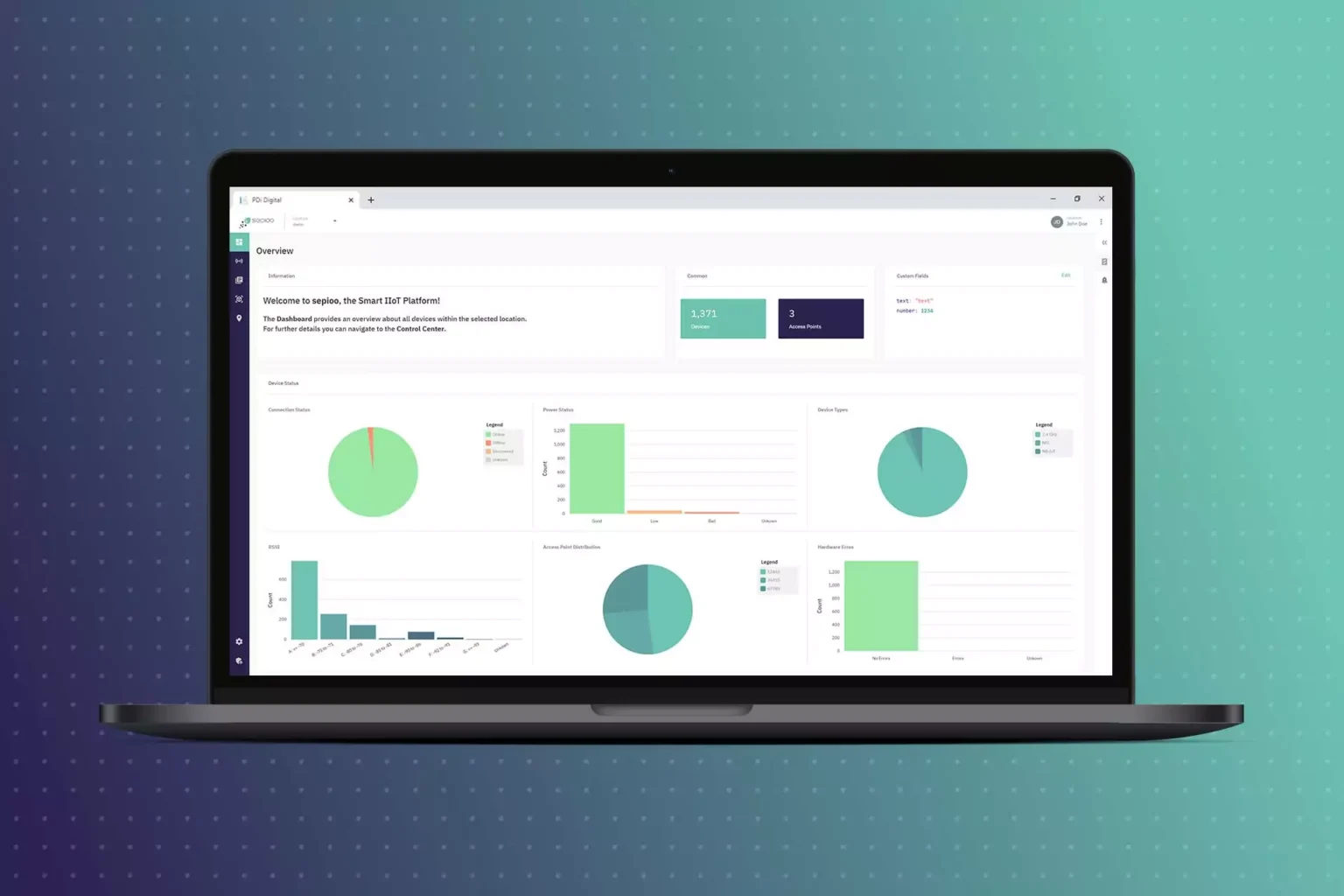

A comprehensive IoT inventory solution

PDi Digital’s sepioo® combines a SaaS platform and IoT devices into one seamless solution that automates and digitizes industrial processes.

-

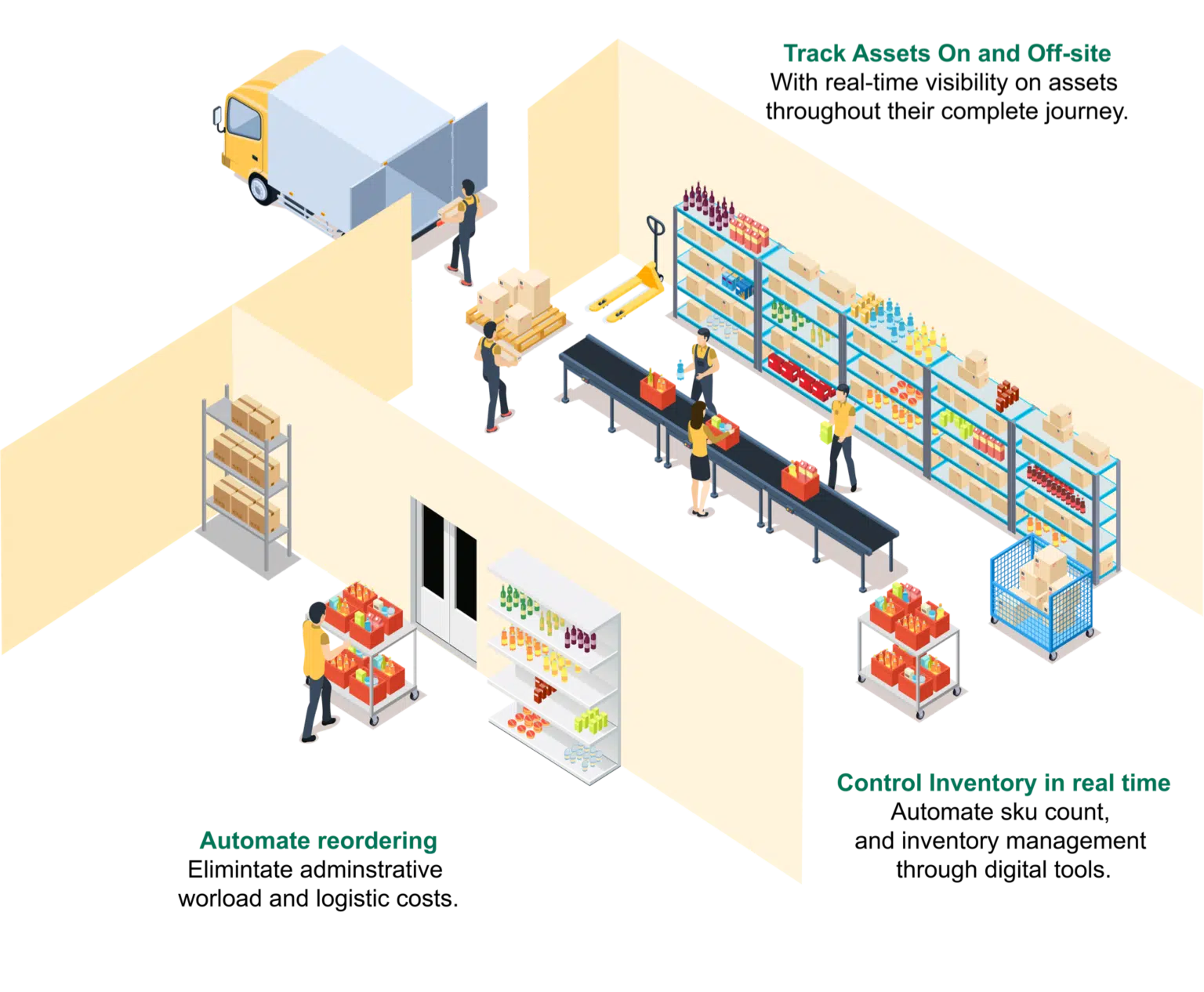

Locate your assets in real time

Access real-time geolocation data with GPS precision, indoor and outdoor, and unlock location-based triggers for your workflows (distance traveled, perimeter).

-

Impact across industries

From manufacturing and logistics to healthcare and automotive, sepioo® is a flexible solution for a wide range of industries.

How the family of products works

Software and hardware systems work together, creating the digital backbone of a smart inventory system.

Why its works for you

Digitalize your paper-based signage

Shift to dynamic information sharing with digital signage and eliminate the need for paper’s associated costs, waste, and labor.

Leverage dynamic data displays

Share information from your systems and ERP where it’s needed in real time, with instant updates on item status or location.

Automate manual processes

Create custom triggers based on location data or actioning buttons. Streamline day-to-day operations and reduce errors with LED hints & pick to light.

Track your assets in real time

Locate your assets with GPS precision — indoor and outdoor — and optimize workflows with location-based triggers.

Enhance day-to-day operations with automated efficiencies

The family of products includes valuable features:

LED signal for pick-and-put by light — reduces search time and picking errors Real-time geolocation tracking — provides visibility on assets throughout the complete operation Trigger actions by button-press & sensors — associates can request instructions, a refill, or help; confirm tasks, count inventory, and implement quality testing

Get detailed information on the family of products

Industrial IoT is Vusion’s smart inventory management technology designed to automate stock control for consumables, components, and production materials. It delivers continuous, sensor-based visibility into inventory levels, eliminating blind spots caused by manual counts. With real-time data, businesses prevent shortages, avoid production delays, and maintain consistently accurate stock across warehouses, stores, and industrial sites.

Industrial IoT uses weight-based and sensor-driven monitoring to track consumption as it happens. When inventory reaches predefined thresholds, the system can automatically trigger replenishment workflows or notify suppliers. This ensures that essential items are always available and that procurement processes stay aligned with actual usage patterns—not historical guesses.

Industrial IoT’s sensors capture micro-variations in stock levels with high precision. They detect changes instantly, even for small parts, technical consumables, or lightweight items. This continuous monitoring eliminates errors common in manual counting and provides a dependable foundation for operations that require accuracy at all times.

Yes. Industrial IoT integrates with major ERP and WMS platforms through standardized APIs. This ensures seamless data flow across procurement, inventory, and supply chain systems. Operational teams benefit from synchronized stock information, automated processes, and a more reliable end-to-end supply chain.

Industrial IoT detects low inventory levels before they impact operations and triggers replenishment immediately. By preventing stockouts and ensuring a steady flow of materials, Industrial IoT protects production timelines, supports uninterrupted store operations, and reduces the risk of last-minute emergency orders.

Yes. Industrial IoT offers centralized visibility across every monitored location. Supply chain, operations, and procurement teams can monitor all sites from a single platform, compare usage patterns, and anticipate upcoming needs more effectively. This multi-site intelligence supports scalable, coordinated operations.

Industrial IoT replaces manual counting with automated, continuous measurement. Teams no longer need to check stock levels item by item or perform periodic audits. This reduces labor time, minimizes operational disruption, and allows staff to focus on higher-value tasks such as quality control, production, or customer service.

Businesses typically see ROI through fewer stockouts, reduced emergency procurement, lower labor costs, and optimized inventory holding. Industrial IoT also decreases material waste, prevents production stoppages, and improves supplier coordination. The result is a leaner, more predictable inventory process that drives measurable operational and financial performance.

Submit the contact form, and we’ll make sure it gets to the right person. They’ll be in touch as soon as possible.

We’ll identify the right solutions and technologies to fit your business needs and show you how they can work for you.

Every business and brand has unique needs. We’ll create a plan that helps you achieve your goals and makes immediate impact.